Product FAQ

What is a high-alumina liner?

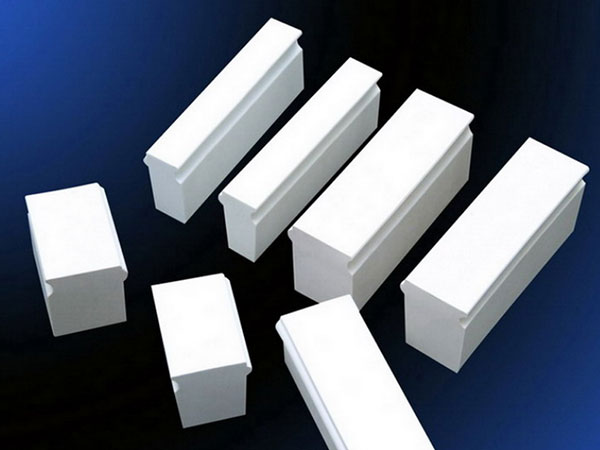

High-alumina liners are wear-resistant and corrosion-resistant liners made of high-alumina materials, primarily used in industrial equipment that needs to withstand high-intensity friction and chemical corrosion. Their core component is alumina (Al₂O₃), and they are available in several grades (e.g., 48%-99.9%) depending on their content. They possess high hardness, high wear resistance, high corrosion resistance, and good thermal stability.

Main Characteristics:

High Wear Resistance: Significantly higher hardness than ordinary materials, effectively resisting impacts and wear during equipment operation.

Corrosion Resistance: Resistant to corrosion from acids, alkalis, and other chemicals, suitable for harsh environments such as chemical and metallurgical industries.

Thermal Stability: High refractoriness of 1750-1790℃, high load softening temperature, suitable for high-temperature operating conditions.

Smooth Surface: Reduces frictional resistance, lowers energy consumption, and improves equipment operating efficiency.

High-alumina liners are widely used in equipment such as ball mills and hydrocyclones to protect the cylinder from wear, while also serving as grinding media (such as high-alumina ceramic balls) to improve material crushing efficiency. For example, in the mining, cement, and ceramics industries, high-alumina lining bricks can extend equipment life and reduce maintenance costs.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China