Cement Grinding Ball Mill

Cement Raw Mill

Cement Raw Mill Working Principle

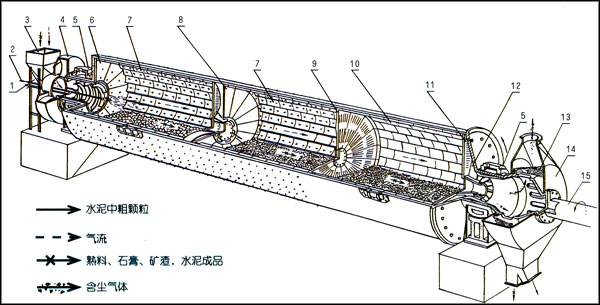

As a professional cement machine, cement ball mill is the most important cement production equipment in the cement production process. The produced cement clinker (and gelling agent, performance adjustment materials, etc.) spirally and uniformly enters the cement mill's grinding chamber through the inlet, where there are lining boards and steel balls of different sizes and sizes. The centrifugal force generated by the rotation of the cement mill cylinder brings the steel ball to a certain height and then falls, causing a heavy blow and grinding to the cement clinker. After rough grinding in the grinding silo, it enters the second silo. This is the cement clinker that basically meets the requirements of the clinker particle size in the cement production. It is further ground with the grinding media in the second silo and has reached a high output. , High-quality cement production requirements.

Cement Raw Mill Product Advantages

1. Cement Raw Mill Suitable for processing hard materials.

2. Cement Raw Mill can be operated continuously without affecting the oil filling of the roller bearing chamber during operation.

3. Low power consumption, high efficiency, convenient installation and maintenance.

4. Low failure rate and long service life, 3-5 times that of ordinary Raymond mills.

5. The cement raw material mill has low noise and low vibration.

Cement Raw Mill Technical Parameter

| Model | Shell rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity | Motor power(kw) | Weight(t) |

| (t/h) | |||||||

| Φ900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| Φ900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| Φ1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Φ1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Φ1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

| Φ1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| Φ1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| Φ1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| Φ2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

| Φ2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

| Φ2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| Φ2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| Φ2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Φ2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Φ2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

| Φ2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| Φ2700*4000 | 20.7 | 40 | <=25 | 0.074-0.4 | 12-80 | 400 | 94 |

| Φ2700*4500 | 20.7 | 48 | <=25 | 0.074-0.4 | 12-90 | 430 | 102 |

| Φ3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | ----- | 800 | 137 |

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China