Ore Grinding Ball Mill

Tungsten Ore Ball Mill

Tungsten ore overflow ball mill is a common type of grinding mill. Its working principle is based on the overflow and reflux of the warehouse. Below, we will introduce the working principle of tungsten ore overflow ball mill in detail and share how to make tungsten ore overflow. Tips for efficient grinding of ball mills.

The structure of the tungsten ore overflow ball mill is simpler than that of the grid ball mill. Except for some different structures at the ore discharge end, everything else is roughly the same as the grid ball mill. The main difference is that there is no grid plate and the inner surface of the hollow journal bushing at the discharge end It is equipped with a spiral square and a spiral blade with the opposite direction of rotation of the mill. The purpose is to prevent water balls or coarse ore blocks from being discharged together with the slurry. The ore discharge of the tungsten ore overflow ball mill is based on the slurry itself being higher than the hollow journal lining. The lower edge of the sleeve causes self-flow overflow, so the liquid level of the slurry in the cylinder is higher than that of the grid ball mill.

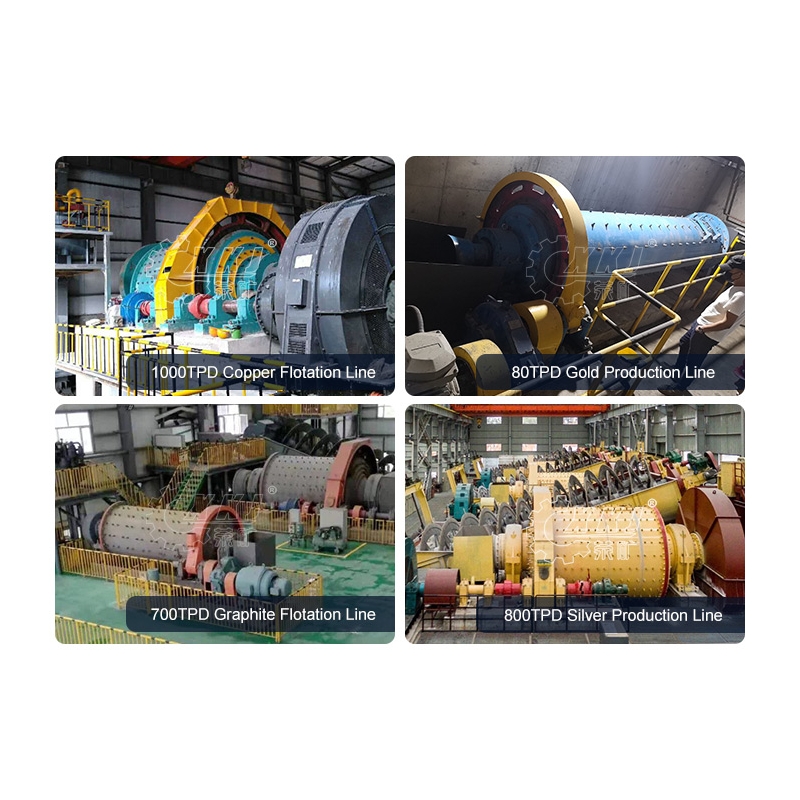

Our company can provide turnkey services for our customers' mineral processing plants, including research, design, manufacturing, installation and commissioning, personnel training, after-sales service and processing plant management. It is our company's goal to become one of the satisfied suppliers of tungsten ore overflow ball mills at home and abroad, so we do our best every step of the way. So far, we have developed six main product lines: crushing equipment, grinding equipment, classification equipment, flotation equipment and gravity separation equipment, and sand making and washing equipment. We carry out strict quality control in every step of producing and delivering products, and we have passed ISO9001:2008 international quality certification. Our company has been rated as a contract-honoring and trustworthy enterprise and an advanced after-sales service unit for many times; it has an import and export license for mineral processing equipment. Our products have been selling well all over the country and exported to dozens of countries overseas for many years.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0086 0371-65091987

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China