Industry news

What equipment is needed to build a graphite beneficiation plant?

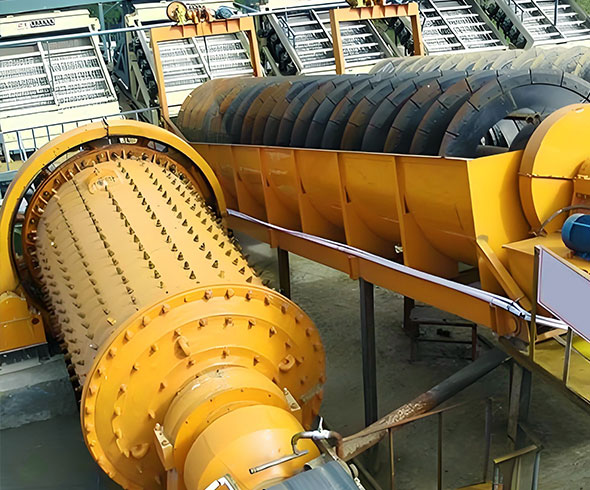

Crushing and grinding system, core equipment of graphite ore dressing plant, jaw crusher (PE600×900 type) processes raw ore to ≤150mm, equipped with GZT series vibrating feeder. Configuration plan of core equipment of graphite ore dressing plant

1. Crushing and grinding system

Coarse crushing equipment

Jaw crusher (PE600×900 type) processes raw ore to ≤150mm, equipped with GZT series vibrating feeder (processing capacity 80-150t/h). Hard rock ore needs to be replaced by hydraulic cone crusher, and the crushing ratio can reach 5:1.

Ultrafine grinding equipment

Vertical roller mill (LUM1125 type) grinds ore to 45-75μm, and equipped with turbine classifier to achieve particle size control. High-purity graphite production line needs to be equipped with stirred mill (JM-1000 type), which reduces energy consumption by 30% compared with traditional ball mill.

2. Sorting and purification equipment

Flotation unit

XCF/KYF flotation machine combination processes -0.074mm particle size, and the reagent system is kerosene 100-200g/t+2# oil 20-50g/t. The selected section needs to be equipped with an adjustable aeration flotation column (Φ3×6m).

High-frequency screening system

GPS high-frequency vibrating screen (screen aperture 0.15-1mm) cooperates with the cyclone group (FX350-GT) to form a closed-loop classification, and the fine particle recovery rate is ≥92%.

3. Dehydration and drying equipment

Concentration and filtration system

NT-30 high-efficiency concentrator (processing capacity 25m³/h) is used in combination with plate and frame filter press (XMZ500/1500 type), and the moisture content of the filter cake can be reduced to 18%-22%.

Microwave drying line

The WZD-60 microwave dryer (power 60kW) has a processing capacity of 1.2t/h, which is 40% more energy-efficient than traditional drying, and the carbon loss rate is controlled within 0.3%.

4. Auxiliary system configuration

Dust removal and environmental protection: LCM-D/G long bag pulse dust collector (filter wind speed 0.8m/min) handles crushed dust

Automatic control: DCS system realizes real-time regulation of grinding concentration (65±2%) and flotation pH value (8-9)

Tailings treatment: Deep cone thickener (Φ15m) cooperates with filter press to realize dry tailings discharge

(Equipment selection needs to be adjusted according to ore characteristics: flake graphite is preferred for flotation, and cryptocrystalline graphite should adopt gravity-magnetic combined process) machine (processing capacity 80-150t/h). Hard rock ore requires hydraulic cone

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China