Autogenous mill

Autogenous Mills

Product Description:

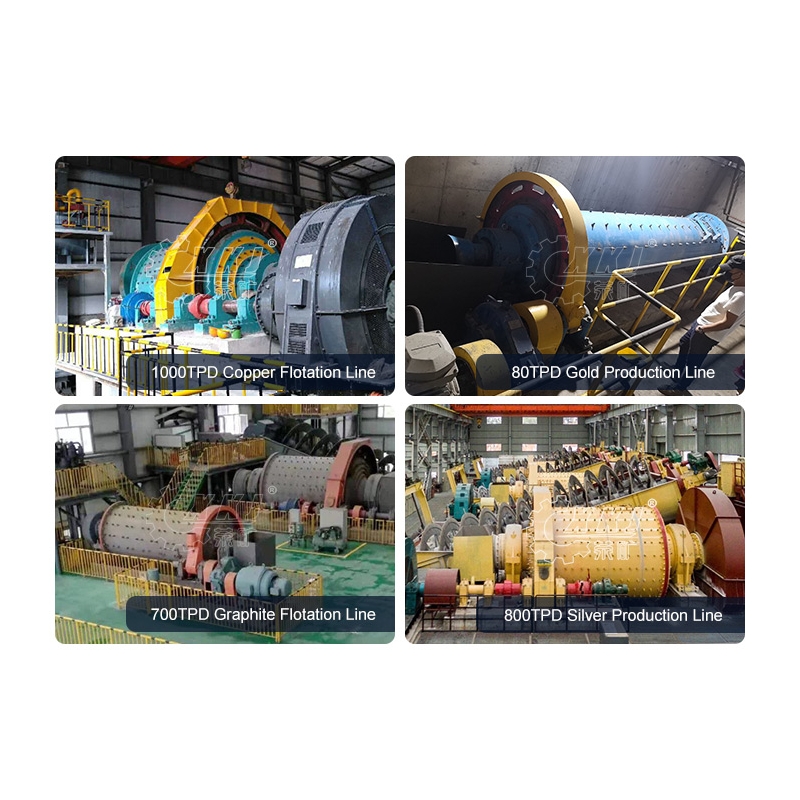

Autogenous and semi-autogenous grinding mills are core equipment in modern mineral processing, specifically designed for efficient ore crushing. Autogenous grinding mills utilize the ore itself as the grinding medium, achieving crushing through mutual impact and grinding. Semi-autogenous grinding mills, on the other hand, add a small amount of steel balls as an auxiliary medium to further enhance crushing efficiency. Both types of equipment are widely used in metal mining industries such as coal, copper, and iron ore, and are particularly suitable for processing high-hardness ores.

Product Features

High Efficiency and Energy Saving: Autogenous grinding mills utilize the ore itself as the grinding medium, reducing steel ball consumption. Semi-autogenous grinding mills use steel balls to assist in improving crushing efficiency, significantly reducing energy consumption.

Structural Innovation: The cylinder adopts a flat design to prevent ore segregation. The liner material is made of medium-low carbon CrNiMo alloy steel, enhancing wear resistance and impact toughness.

Simplified Process: Semi-autogenous grinding mills replace traditional medium and fine crushing and screening stages, shortening the process and reducing dust generation, making them suitable for large-scale mineral processing plants.

Intelligent Control: Equipped with a PLC + touch screen system, achieving automated operation and improving production stability and safety.

Technical Parameters

| Model Number | Diameter (mm) | Length (mm) | Feed Particle Size (mm) | Motor Model | Power (kW) | Voltage (V) | Weight (t) |

| ZMJ4014 | 4000 | 1400 | <350 | JR138-8 | 245 | 10000 | 75 |

| ZMJ4018 | 4000 | 1800 | <350 | JR1410-8 | 320 | 10000 | 82 |

| ZMJ5518 | 5500 | 1800 | <400 | TDMK800-36 | 800 | 10000 | 175 |

| ZMJ6522 | 6500 | 2200 | <400 | TDMK1600-40 | 1600 | 10000 | 280 |

| ZMJ7525 | 7500 | 2500 | <400 | TM2500-16 | 2500 | 10000 | 455 |

| ZMJ7528 | 7500 | 2800 | <400 | TM2500-16 | 2500 | 10000 | 465 |

Application Scenarios

Metal Ore Beneficiation: Suitable for gold, copper, and iron ores, exhibiting excellent performance when processing high-hardness ores.

Large-Scale Mines: Semi-autogenous mills are widely used in extra-large concentrators, simplifying processes and reducing environmental impact.

Environmental Requirements: Reduces dust and noise, meeting modern clean production requirements in mines.

Market Advantages

Cost-Effectiveness: Semi-autogenous mills save on investment and operating costs, have low steel ball consumption, and minimal impact on subsequent flotation operations.

Technological Leadership: Employs an arc-shaped discharge end and optimized mixed ball diameter scheme to improve discharge efficiency and reduce stubborn rock accumulation.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China