Product FAQ

Recommended small gold ore ball mill with a processing capacity of 60 tpd

For small-scale gold ore beneficiation with a daily processing capacity of 60 tons (60 tpd), the ball mill, as the core grinding equipment, needs to balance processing capacity, energy efficiency, and operational stability. Based on the characteristics of gold ore and the actual conditions of a small-scale beneficiation plant, the following suitable solutions are recommended:

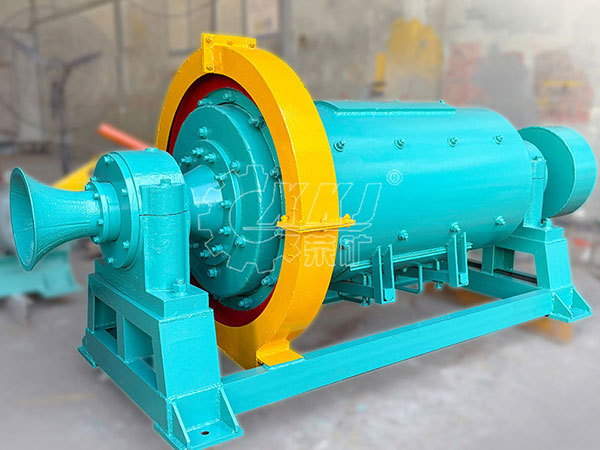

Wet Overflow Ball Mill: A High-Efficiency and Energy-Saving Choice

The wet overflow ball mill is specifically designed for fine grinding of gold ore. Its slow-speed drive system reduces start-up energy consumption and minimizes equipment impact. For a 60 tpd scale, it is recommended to choose a compact model with a processing capacity of 1-5 tons/hour, such as a small laboratory ball mill or a micro continuous ball mill. This type of equipment, by optimizing the cylinder speed and media ratio, can crush gold ore to a suitable flotation particle size (typically -200 mesh accounting for more than 70%), improving recovery rates. Its simple structure and convenient maintenance make it suitable for small mines with unstable power supplies.

Key Considerations for Selection

Matching: Ensure the ball mill's processing capacity is compatible with the crushing section to avoid overloading or capacity bottlenecks.

Material Wear Resistance: High-chromium alloy liners or ceramic linings are used to extend service life and prevent iron contamination.

Power Compatibility: Electric motor drive (e.g., a 11kW small motor) is preferred; diesel power can be considered as a backup if there is a power shortage in the mine.

Maintenance Convenience: Modular design models are selected for easy and quick replacement of wear parts, reducing downtime risk.

In summary, for a gold ore beneficiation plant with a processing capacity of 60 tpd, a wet overflow ball mill is recommended as the mainstream choice. Specific model selection requires a comprehensive evaluation based on ore hardness, final product particle size, and site conditions to ensure a balance between efficiency and economy.

Categories

News

Contact Us

Contact: XKJ GROUP

Phone: 0086 138 3714 0277

Tel: 0371-65751333

E-mail: sales01@xkjgroup.com

Add: Xing yang city, Zheng zhou city, Henan province, China